Asset Administration Shell

A system for managing and monitoring industrial assets in manufacturing environments, providing standardized interfaces for communication and data exchange.

Project Overview

The Asset Administration Shell (AAS) is a key component of Industry 4.0, serving as a digital representation of physical industrial assets. This project implements a comprehensive system for creating, managing, and interacting with these digital twins.

By providing standardized interfaces and data models, the AAS enables seamless integration of manufacturing equipment, sensors, and control systems. This implementation focuses on real-time monitoring, data exchange, and standardized communication protocols.

The system helps manufacturing companies achieve greater efficiency, predictive maintenance, and improved decision-making through comprehensive digital representation of their physical assets.

Key Features

Asset Data Management

Comprehensive storage and management of asset information, including specifications, status data, historical data, and operational parameters.

API Integration

Standardized REST API interfaces for communication with various systems, ensuring interoperability across manufacturing and management systems.

Real-time Monitoring

Live monitoring of asset performance, status, and operational metrics with dashboards and visualization tools for effective oversight.

Digital Twin Modeling

Creation and management of comprehensive digital representations of physical assets, enabling simulation and predictive analysis.

Technical Implementation

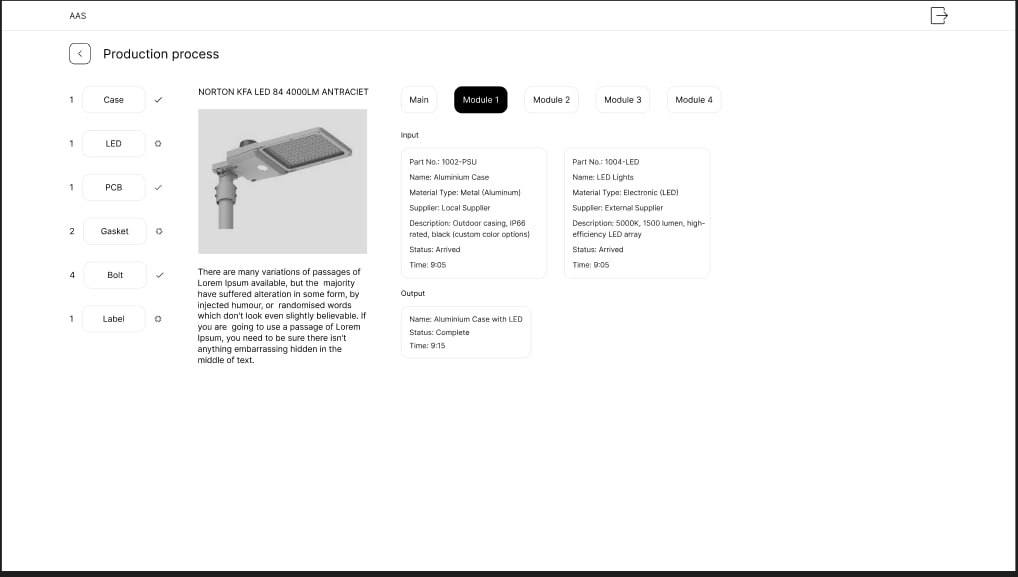

Management Dashboard

The management dashboard provides a comprehensive overview of all assets, including production metrics, material usage, and status indicators. The system tracks key performance indicators and presents them in an intuitive interface for operators and managers.

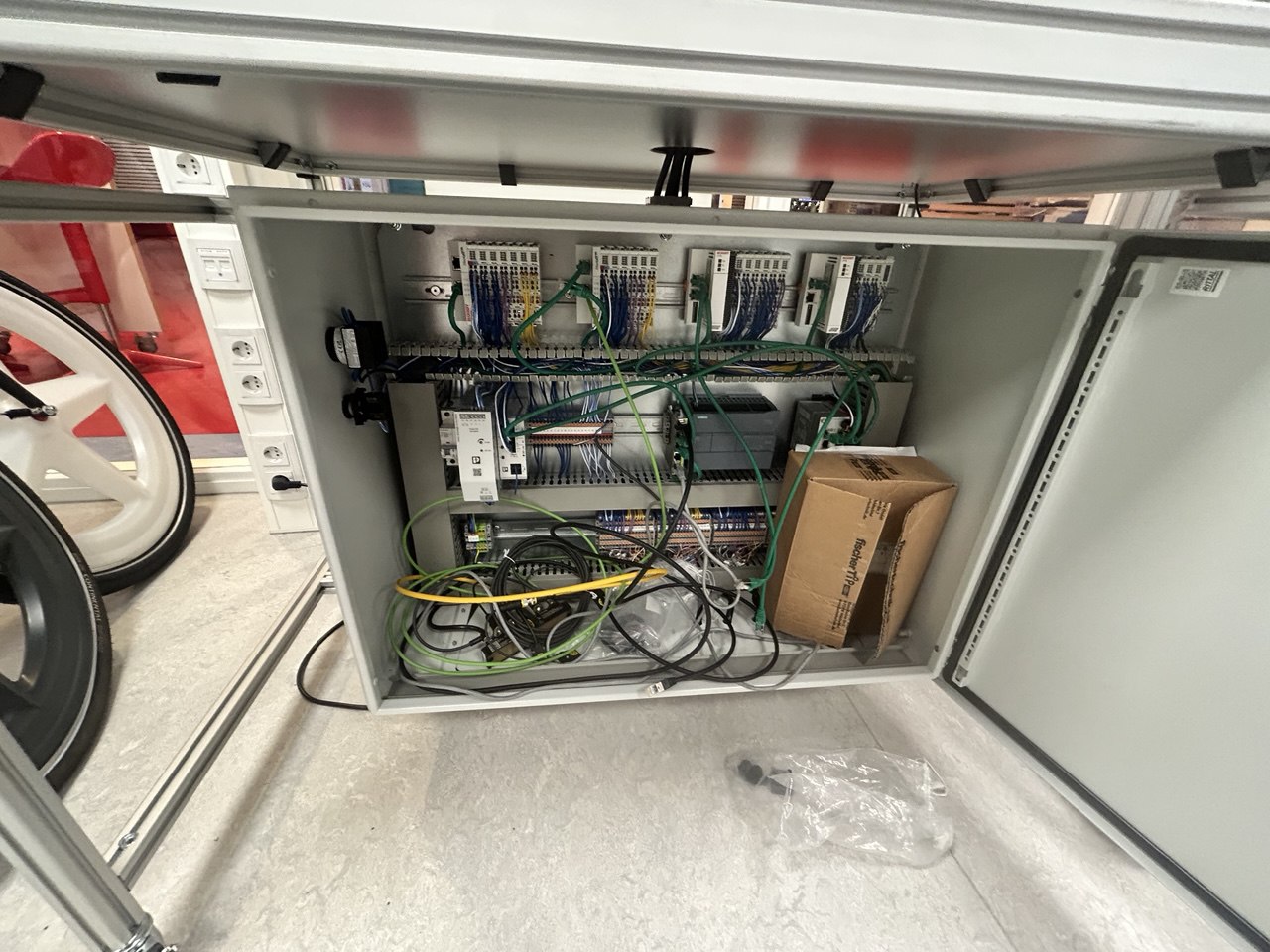

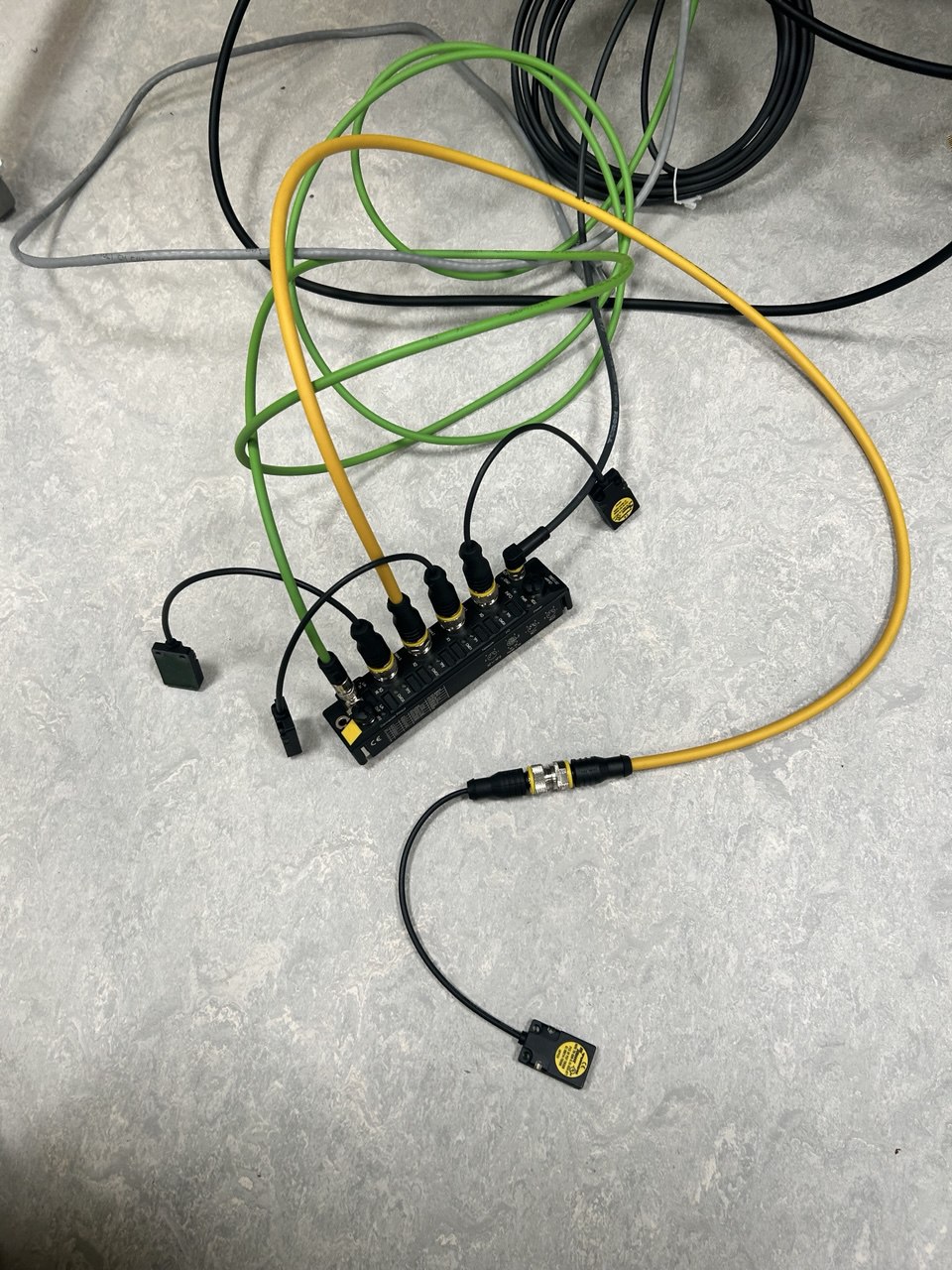

Hardware Integration

The AAS system integrates with industrial hardware through standardized protocols and interfaces. This ensures compatibility with a wide range of manufacturing equipment, sensors, and control systems.

The system includes specialized connectors and adapters for different types of industrial equipment, enabling seamless data exchange and control capabilities across the manufacturing environment.

Project Outcomes

- •20% reduction in asset downtime through predictive maintenance capabilities

- •Improved interoperability between different manufacturing systems and equipment

- •Enhanced visibility into production processes and asset performance

- •Standardized data exchange formats enabling better integration with enterprise systems

- •Scalable architecture supporting hundreds of connected industrial assets